Vertical Reflow Oven MSTX-600

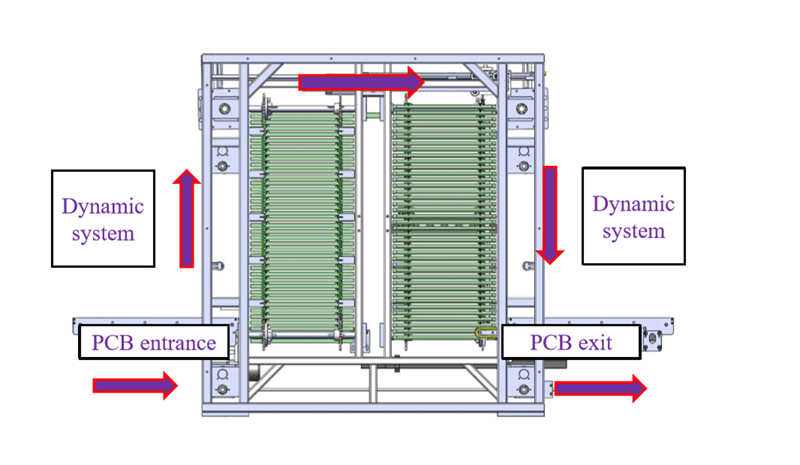

- PCB size: 600x600mm (L*W)

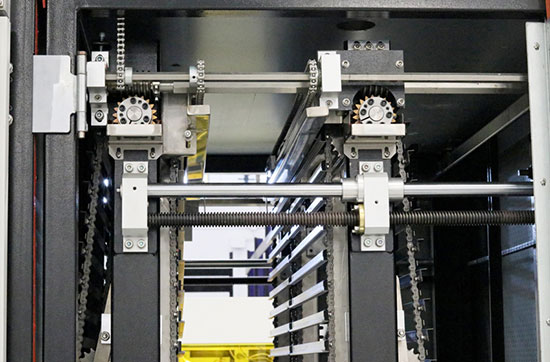

- Conveyor: Bottom and return

- Distance between slots: 50mm

- Numbers of slots: front 32 cages, rear 32 cages

- Weight: More than 6kg per layer

- Zones: 3 Temperature zones and 5 probes

- Heating control:

- Temperature monitoring probes (thermocouple)

- Heating speed can be adjusted

- Photoelectric sensor: Detect the position of PCB

- Fiber optic sensor: Detect the position of PCB

- Lifting limit detection fiber

- Width adjusting device: The moving rail moves to adjust the width

- Safety: CE Safety measures and protection devices

Photoelectric Sensor

Fiber Optic Sensor

| Model | MSTX-600 |

| General specifications | |

| Dimension | 1800*1880*2200 mm-L*W*H |

| Weight | 1600KG |

| Heating zone qty | Top 2, bottom 2 |

| Direction | Left to right, up to bottom |

| Power | 3P 380V 50/60HZ |

| Total power | 26.4KW |

| Running power | 17KW |

| Conveyor | |

| PCB width | 100*100-600*600mm |

| PCB thickness | 2*5mm – pallet:5*45mm |

| PCB bending rate | Up& bottom ≤1.0mm |

| Conveying height | 900±50mm |

| Gap height | ≥50.8mm |

| Stocking PCB qty | Top:32 layers – bottom:32 layers |

| Conveying method | Support strip |

| Distance | 25.4mm |

| Conveying speed | 0-2000mm/min adjustable |

| Bearable weight | 6KG/layer |

| Property | |

| Heating modular | 4pcs |

| Heating time | 18min |

| Oven surface temp. | ≤65°C (under room temp.) |

| Controllable temp | Indoor 200°C |

| Heating compensation temp | ±3°C |

| Control accuracy | ±3°C |

| Software | |

| Control method | Touch screen+ PLC / industrial computer+ PLC |

| Data monitor | Computer data record and enquiry |

| Authorization | Can be set |

| Safety | |

| In accord to national standard | Yes |

| Abnormal temp. stop | Signal of PCB enter and exit, trigger device |

| Heat radiation system | Yes |

| Protection device | Safe guardrail, emergency stop, safe marks |

| Safe device | Open the safety door to alarm and automatically shift to temp. dropping mode |

| Over temp. protection device | Heating stops, PCBs inside come out |

| Fire-proof level | B1/A |

| Service | |

| Warranty | 2 years |

| Scene training | Yes |

| Technique support | 48 hours |

| Intelligent terminal | Available |

| Software upgrade | Free of charge |